Making A Planer Blade Sharpening Jig Homemade Machines & Jigs

This is my second version of a planer knife sharpener, the first one worked well, but is a bit bulky and had some other problems. It was also made for the planer knives I was using at that time, which were thicker than the ones I use now.

To get started and to make the jig as straight and rigid as possible where it holds the knife, I cut a piece of angle steel to about 12″ long:

.jpg)

To remove any bumps or other irregularities, I sanded it flat using a strip (actually an old 2×72 belt from my belt grinder) of sand paper on my flat table saw top:

.jpg)

I drilled two 3/16″ holes for screws and fastened the angle to a piece of hardwood. The hardwood is cut 12″ long and 3/4″ square, and is screwed on so that it lined up perfectly with the edge of the angle steel:

.jpg)

Another piece of hardwood is cut to size for the clamp that will hold the blade. It is 12″ long, 1-1/2″ wide and 1/2″ thick. I cut a shallow rabbet in it for the blade to fit into and used five wood screws to fasten it to the jig:

.jpg)

The screws are tightened to clamp the blade, and loosened to remove it.

.jpg)

Next, I made an arm that is cut to a 45 degree angle at the end. It is 3/4″ plywood and I used 5 minute epoxy to attach it to the jig:

.jpg)

I propped up the arm on the other end to get the angle right. It doesn’t need to be perfect, the main thing is that the angle is close to 45 degrees and that the arm is on the same plane as the blade. Attaching the arm with it on the flat table saw helps keep it lined up.

To reinforce the joint, I added a small piece of 1/2″ plywood and used regular wood glue:

.jpg)

The arm rides on a strip and that can be made from anything, but I had a piece of UHMW plastic on my lumber rack that was nearly the right size:

.jpg)

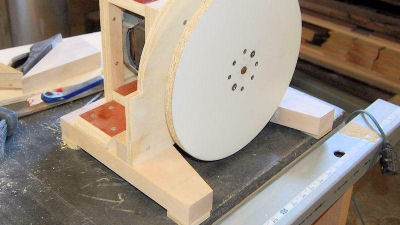

The jig is now finished, but I did cut the arm shorter to make it more compact. I set up the jig on a piece of 5/8″ melamine as a flat surface and I’m using a big, two grit stone for the sharpening:

.jpg)

To lube the stone and wash away the swarf, I’m just using a spray cleaner, but any soapy solution would work:

.jpg)

It takes about 5 minutes to restore the edge, first on the coarse grit side of the stone, and then on the fine side:

.jpg)

These knives were in really bad shape and had some deep nicks that couldn’t be ground out, but the rest of the blade came out razor sharp and cuts very well:

.jpg)

The best strategy would be to sharpen the knives when they start to get dull and not let then get this bad. Doing it that way would take less time and grind away less of the edge. These knives are disposable and for this machine (Dewalt DW735) are not supposed to be sharpened, but I figure one or possibly two wouldn’t hurt, as long as I’m careful to grind each blade equally.

This jig can also be used for jointer knives and can be made specially for a certain lenght – 8″ long for 8″ blades, and so on.

Here’s a short video showing how the jig was built and using it for the first time: